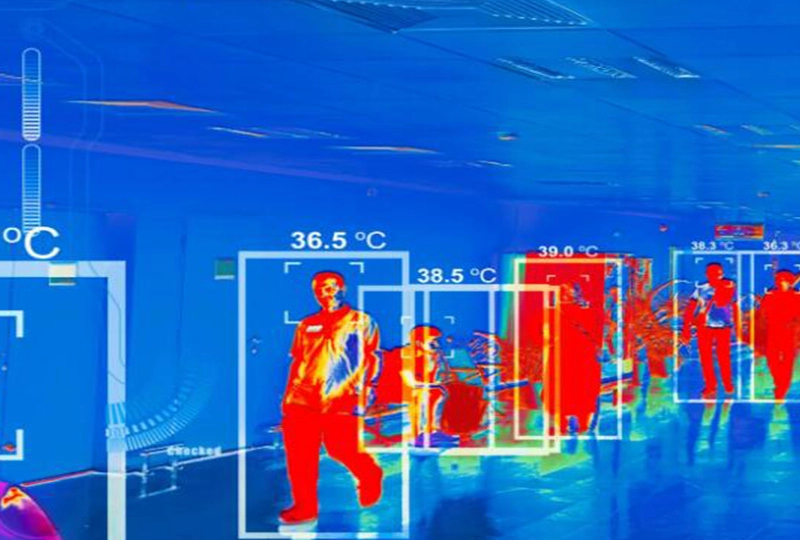

Infrared (IR) materials are essential components in various technological applications, from thermal imaging and optical communication to spectroscopy and defense systems. These IR materials possess the ability to transmit, reflect, or absorb infrared radiation, making them crucial for the performance of IR devices.

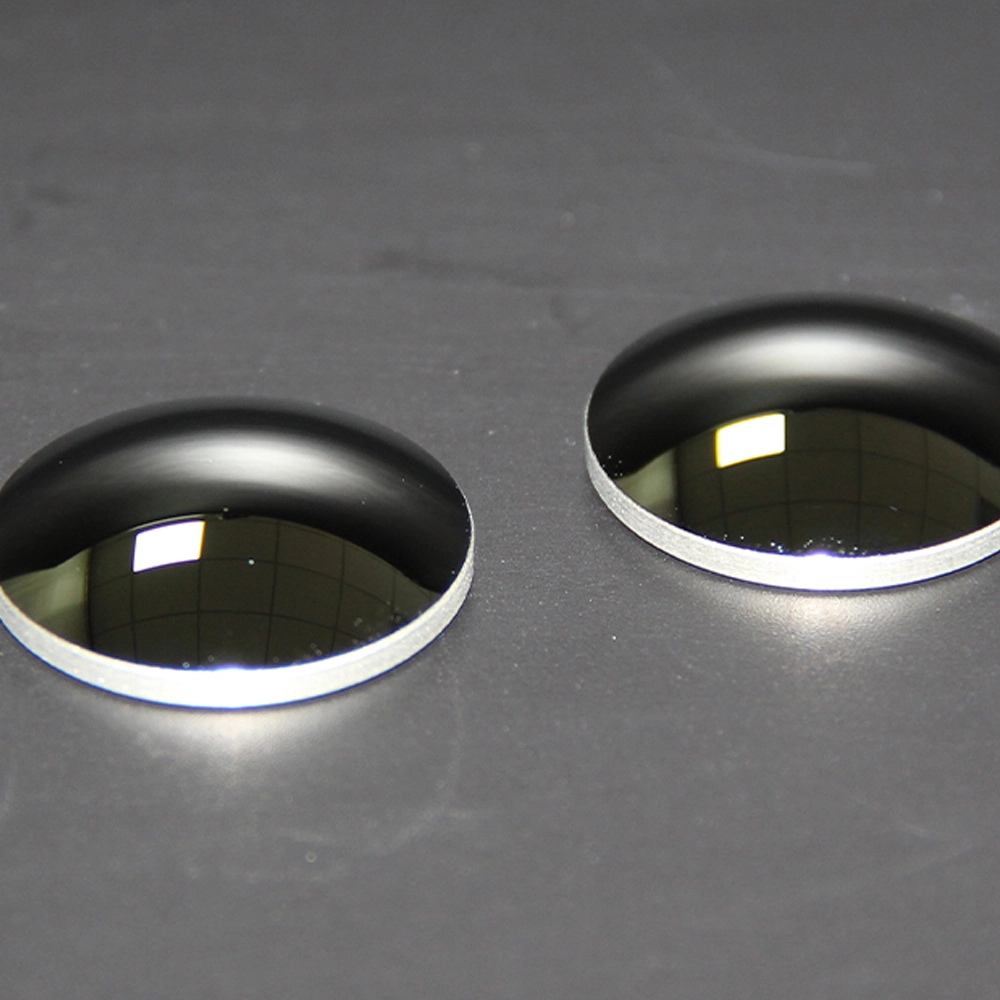

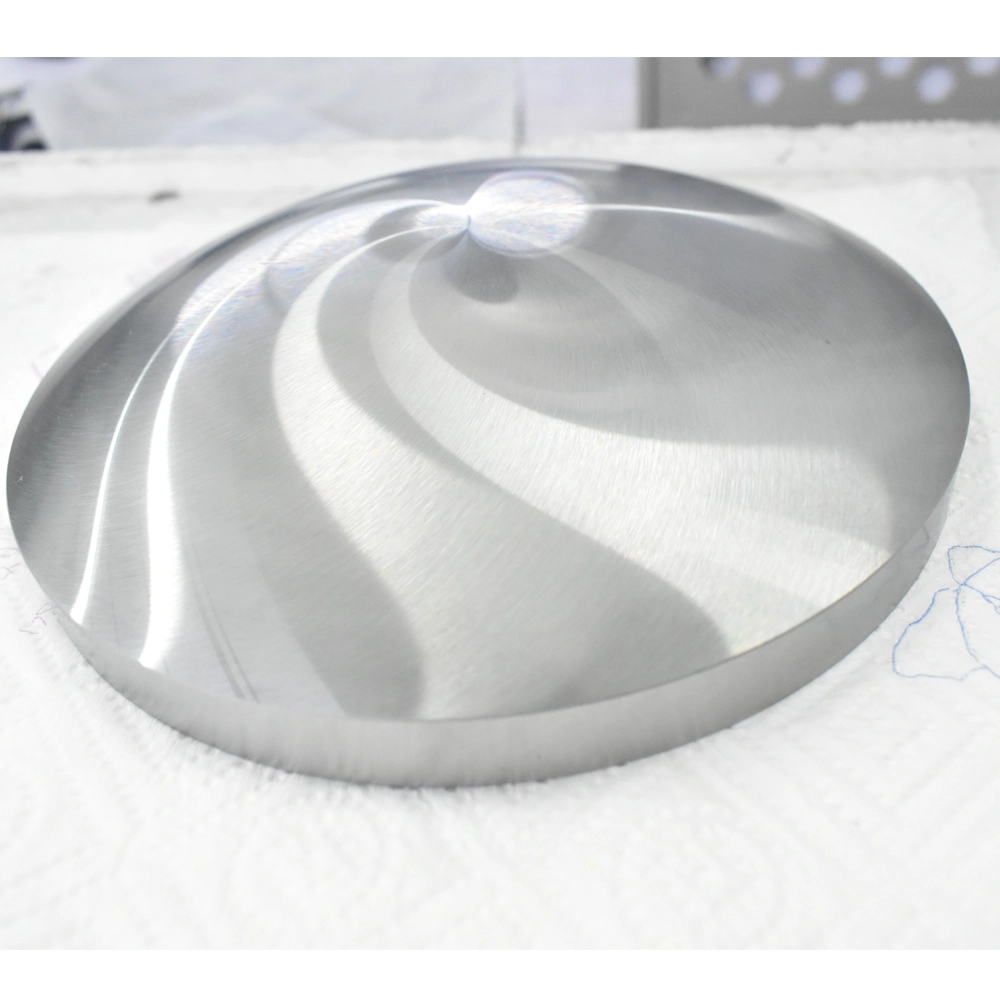

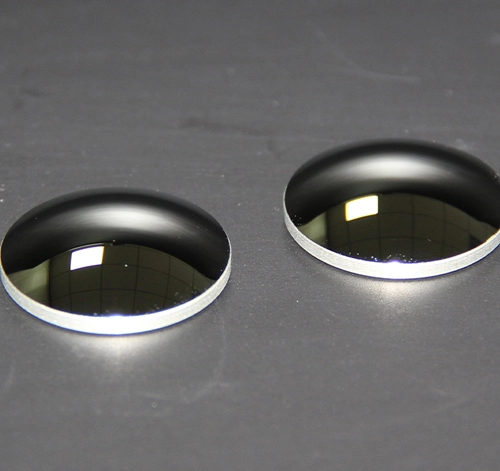

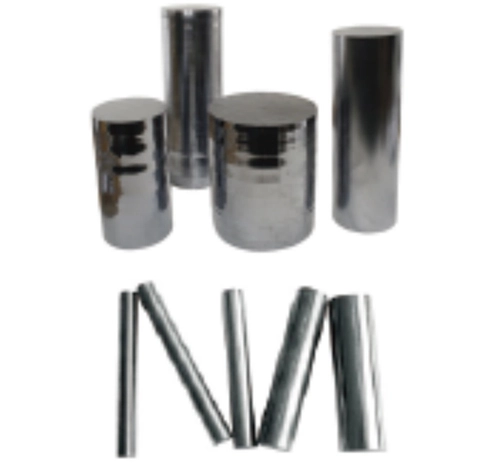

Infrared materials enable diverse applications, from thermal imaging to laser systems. Infrared lens materials like Ge, Si, ZnS, ZnSe are used in optics. IR optical materials including PbS, CdS, and LiNbO3 enable photonic devices and fiber optics. Infrared coating materials of SiO2, Si3N4, Al2O3, and TiO2 enhance IR optic performance. Infrared filters, both interference and absorption-based, are crucial for spectroscopy and sensing. Infrared transparent materials like metals, CNTs, and conductive polymers provide shielding. Infrared reflective materials, such as metal films and multilayer dielectrics, control IR energy for mirrors and windows. IR transparent materials, e.g. PbS, HgS, MgF2, CdTe, enable IR windows, lenses, and fibers. Integrating these IR materials drives advancements in thermal imaging, spectroscopy, and communications.

en

en

Call us on:

Call us on:  Email Us:

Email Us:  No.9 Zhongxing East Road, Lishui Economic Development Zone, Nanjing, Jiangsu, China

No.9 Zhongxing East Road, Lishui Economic Development Zone, Nanjing, Jiangsu, China